-

Evolved Forging Process

Our SuperSAGTM forged steel balls have evolved from standard designs, informed by years of customer operation insights. We recognize that requirements for forged steel balls vary across different operational stages, leading us to continuously adapt our products to meet these diverse needs.

-

Enhanced Performance

We optimize the hardness and toughness of our forged steel balls for diverse applications, using advanced heat treatment to prevent deformation and breakage. This enhances both output capacity and fineness, improving operational efficiency.

SuperSAG customer case

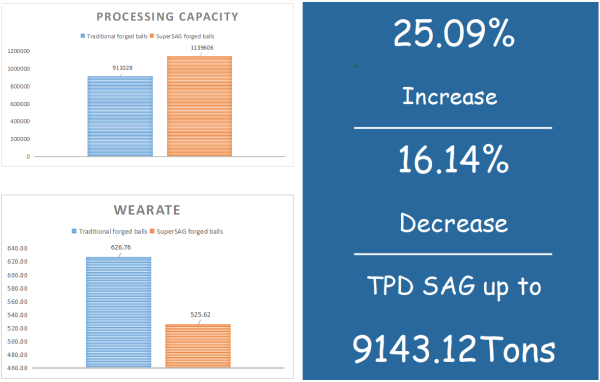

25.09% Increased Output in Ore Processing

SuperSAG at a Copper Mine in Chile

During a 25-day trial, traditional forged balls processed 911,028 tons of ore minerals at this site. In comparison, our SuperSAG forged balls processed 1,139,606 tons of ore minerals in the same timeframe. This represents a significant increase in efficiency, with 25.09% more output achieved using SuperSAG balls.