-

Metallurgy

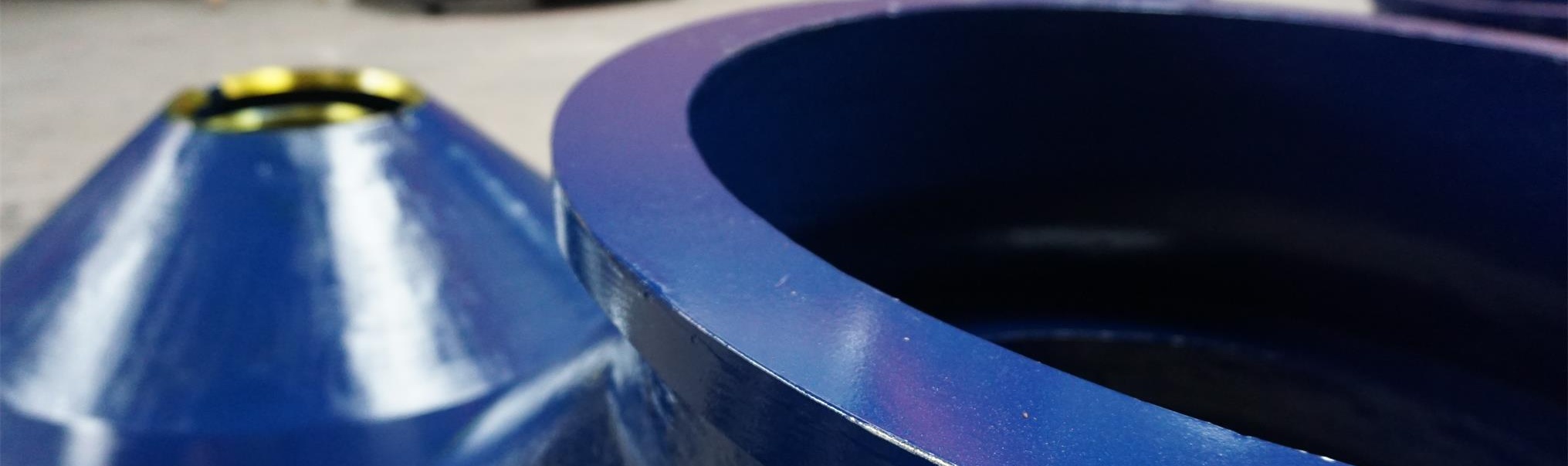

At our facility, we uphold the highest standards for raw material quality and do not compromise to cut costs. Specifically, scrapped manganese steel liners are never used as melting material in our processes.

-

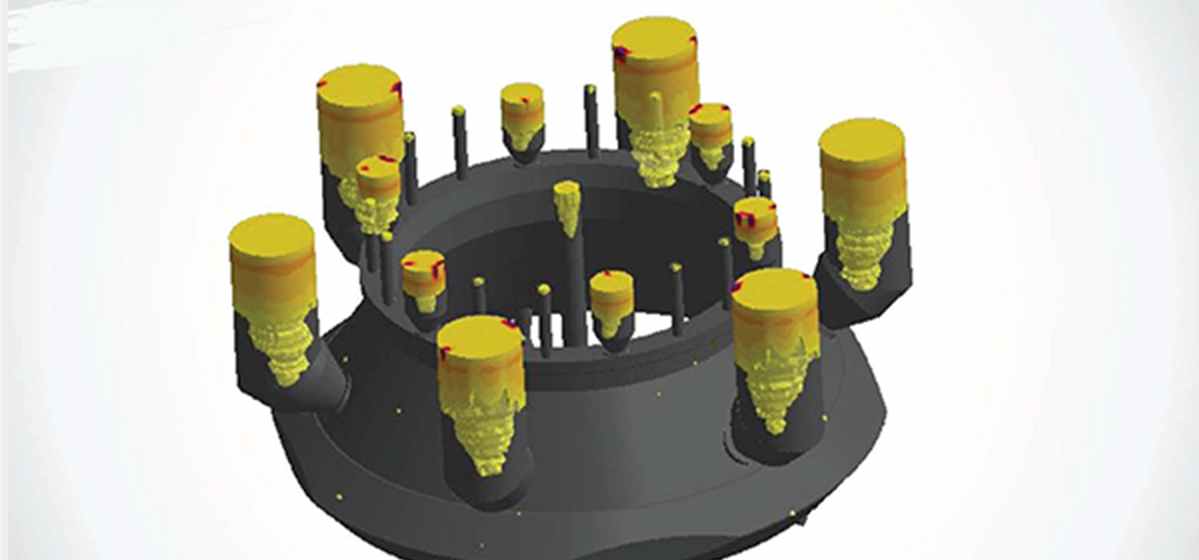

Pouring Design

As a standard procedure, we employ advanced software simulation prior to the molding process. This approach is crucial for identifying and eliminating potential internal defects, thereby ensuring the premium quality of our products.

-

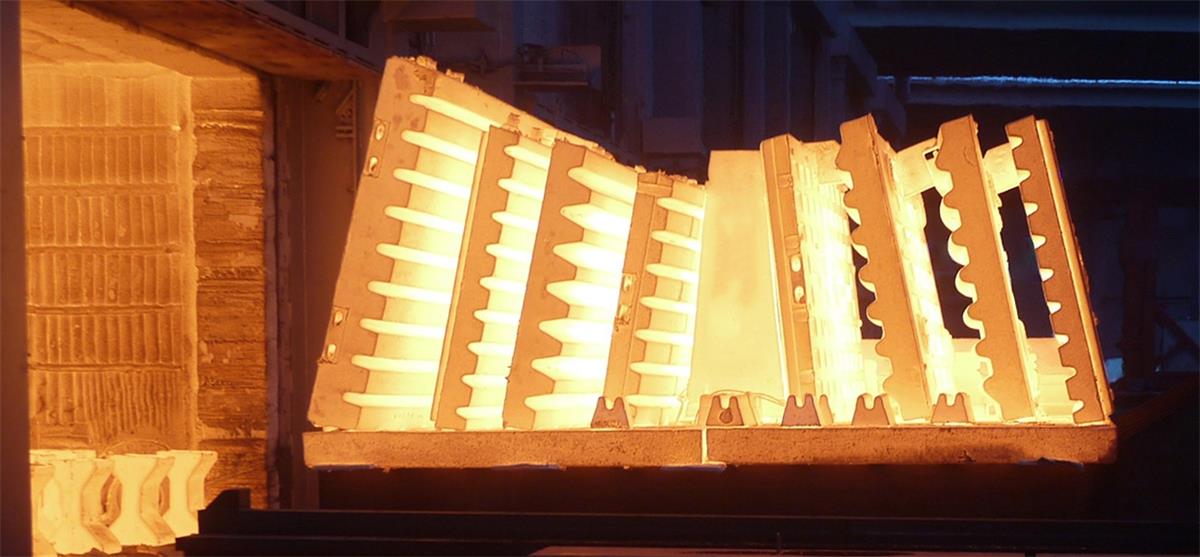

Heat treatment

Key Factors Under Our Control:

- Temperature control

- Furnace loading

- Rapid cooling

Premium Mn customer case

Improved wear life by 23%

Symons 7 crusher wears at an iron mine in Africa

With just standard Atonmec premium Mn solution in 18% Manganese, the wear life of mantles and concaves averagely extended from 350 hours to 430 hours, which also led to a reduction in associated downtime.

Avoided Deformation on Shredder Hammer Pin Hole

4000 HP Shredder at a Scrap Steel Recycling Site in China

The technical enhancement involving a premium Mn solution, combined with an optimized pin hole profile and treatment, effectively reduced deformation and crack risks in the shredder hammer pin holes. This technical solution not only improved the machinery's robustness but also extended the wear life of the manganese steel hammers by an additional 30%.